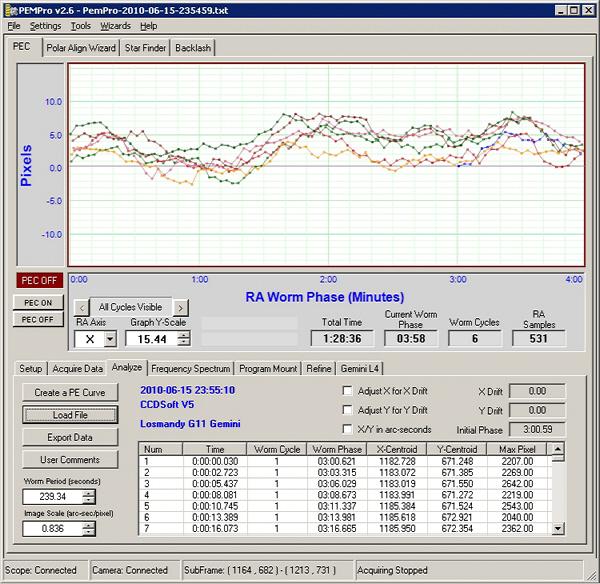

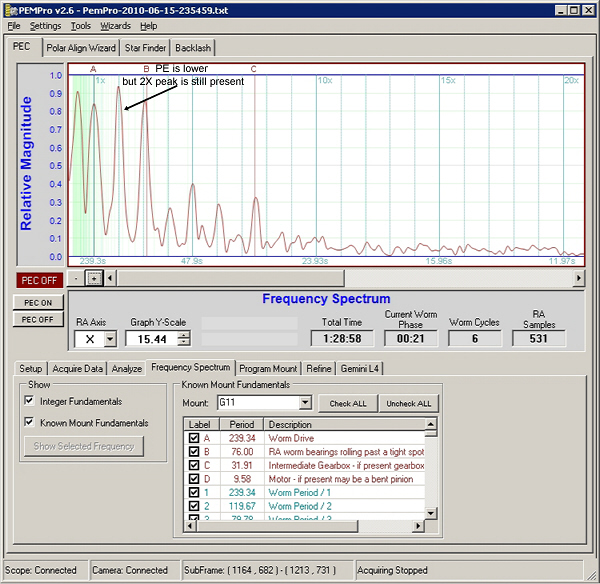

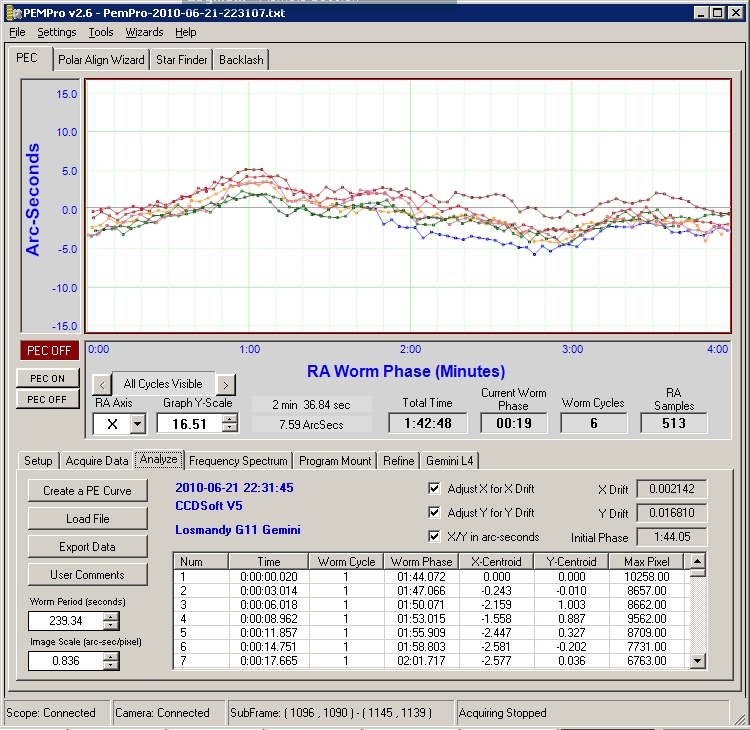

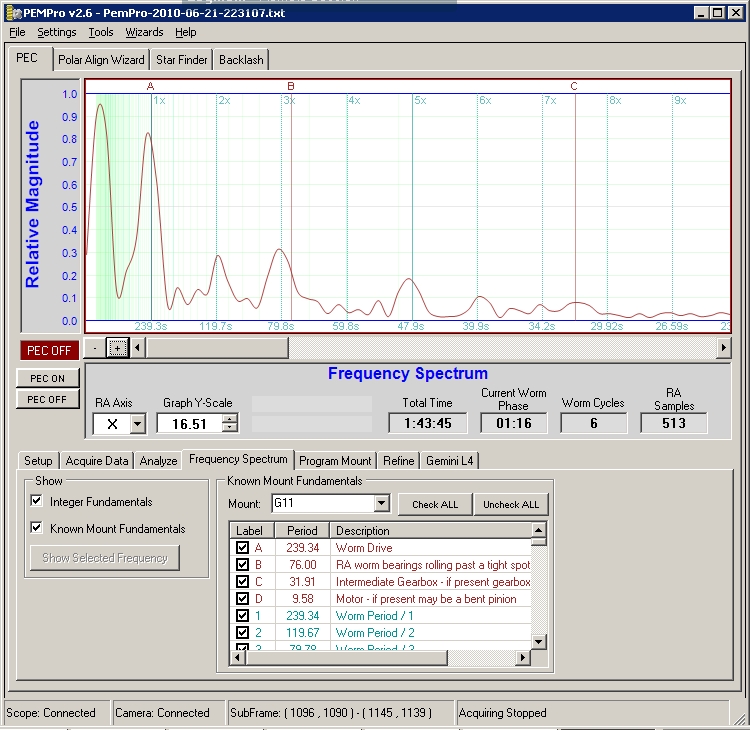

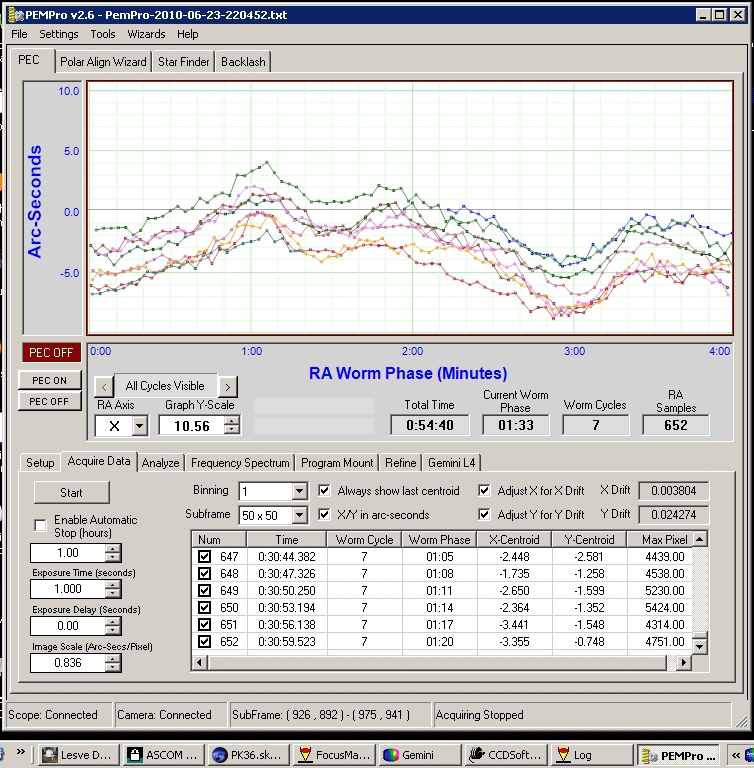

Several nights of testing were performed to evaluate the new block design. Below are the before and after results using PemPro

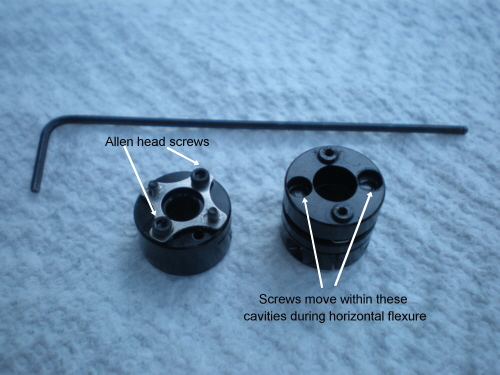

that was used to measure and plot the performance results. My mount is using the brass high precision worm and though this was an improvement over the high precision steel worm that came with it originally, I was never able to get the performance I was expecting with the brass. But, it didn't effect my imaging so I lived with it. That was until I read in the Yahoo Losmandy users group that a one piece worm block was being released. So I quickly bought one knowing well that this design hasn't been proven. But, like so many in that group, tinkering with this mount is easy and Losmandy has a reputation of superb machining.

Some of my expectations for purchasing the new block design were:

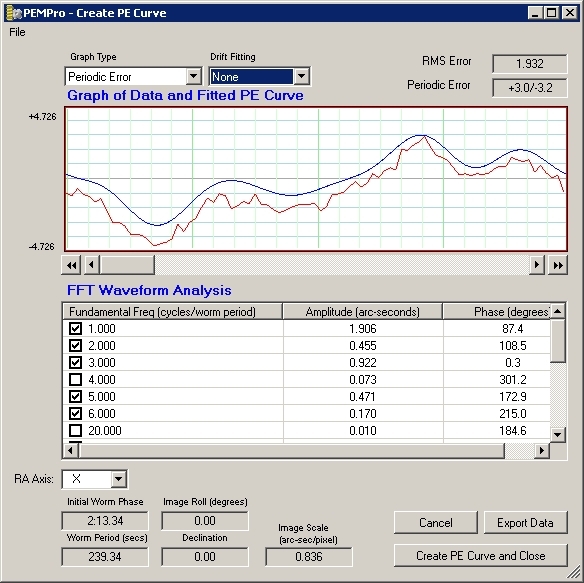

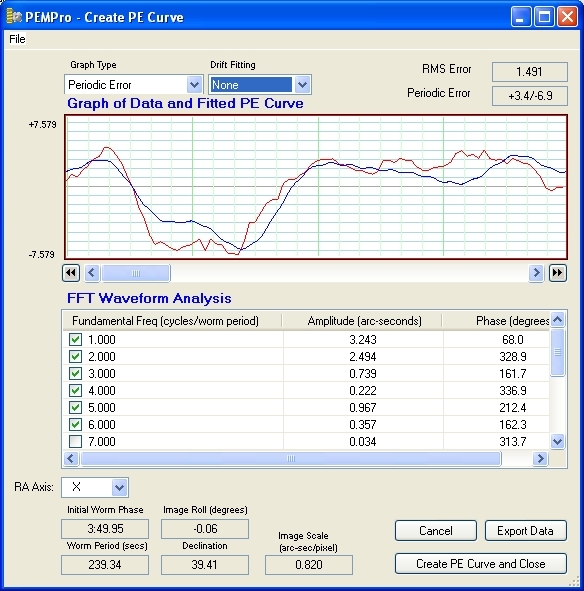

Note: PemPro does allows you to fine tune the PEC profile by adjusting drift and delays. I decided to present the data unmodified for comparisons.

Each persons mount will behave differently with fine tuning which is why I left these results untouched.

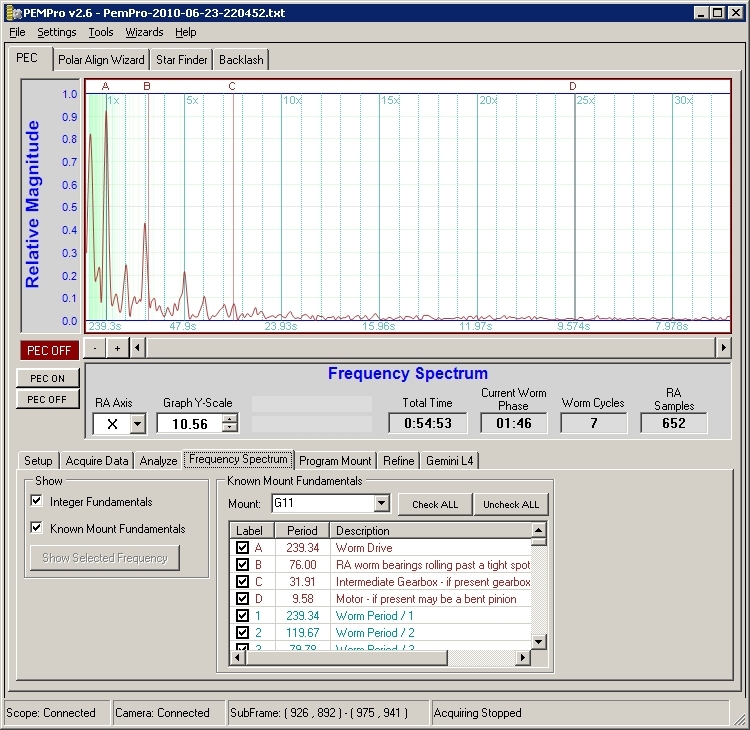

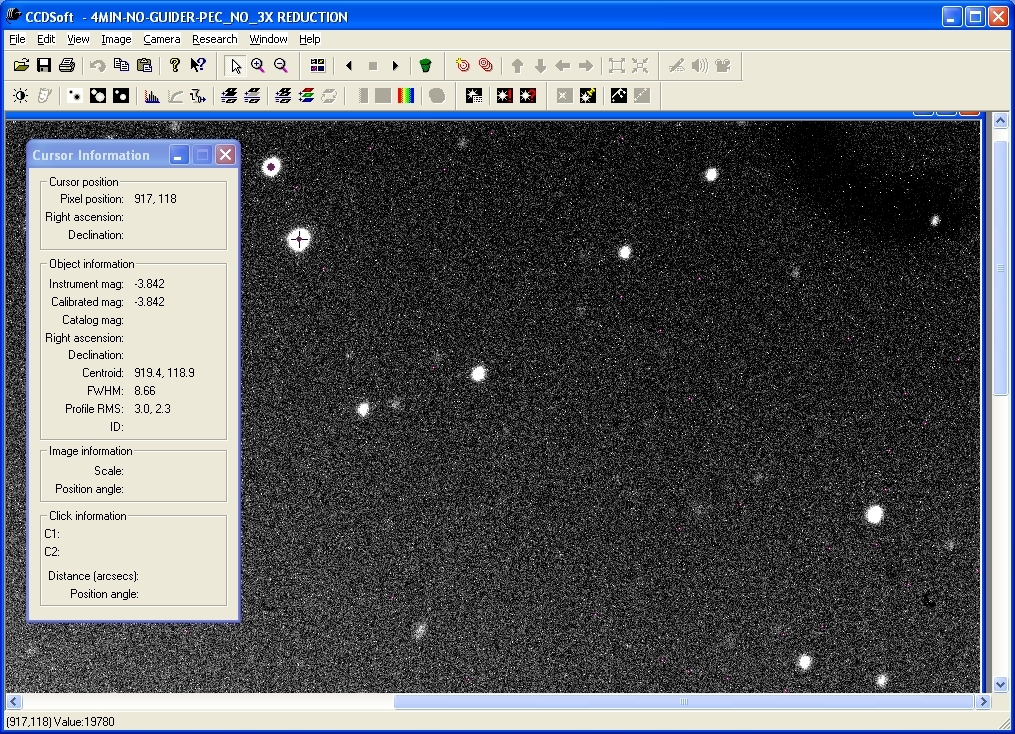

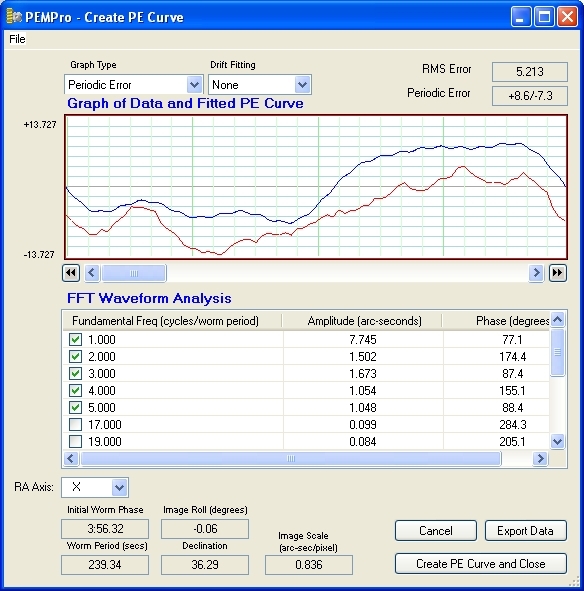

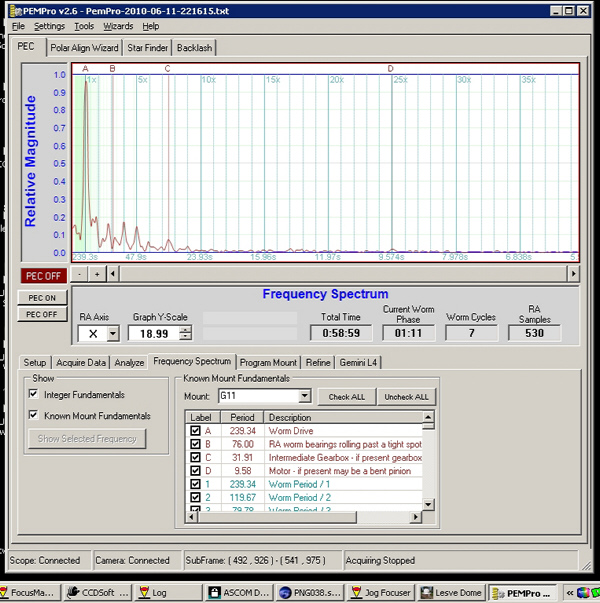

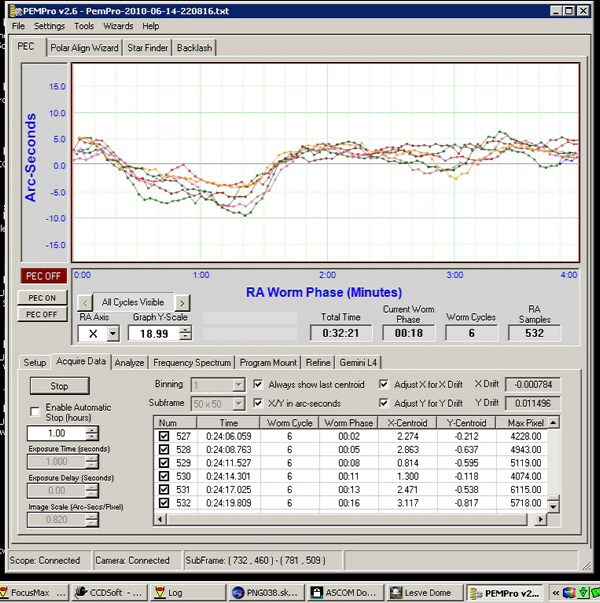

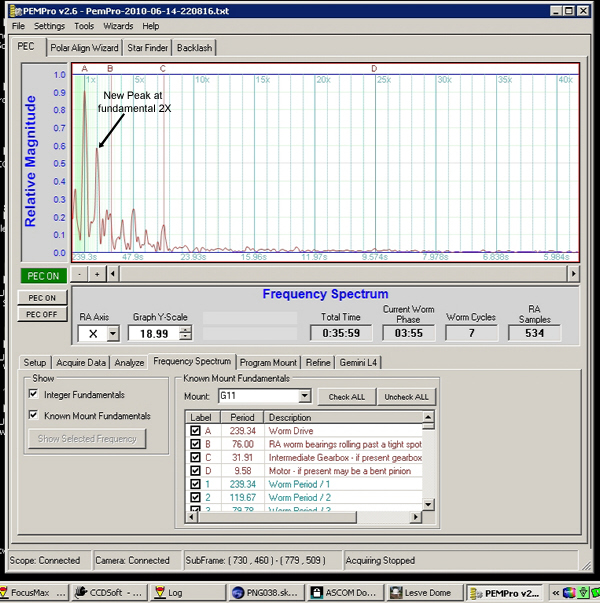

Before Upgrade Results

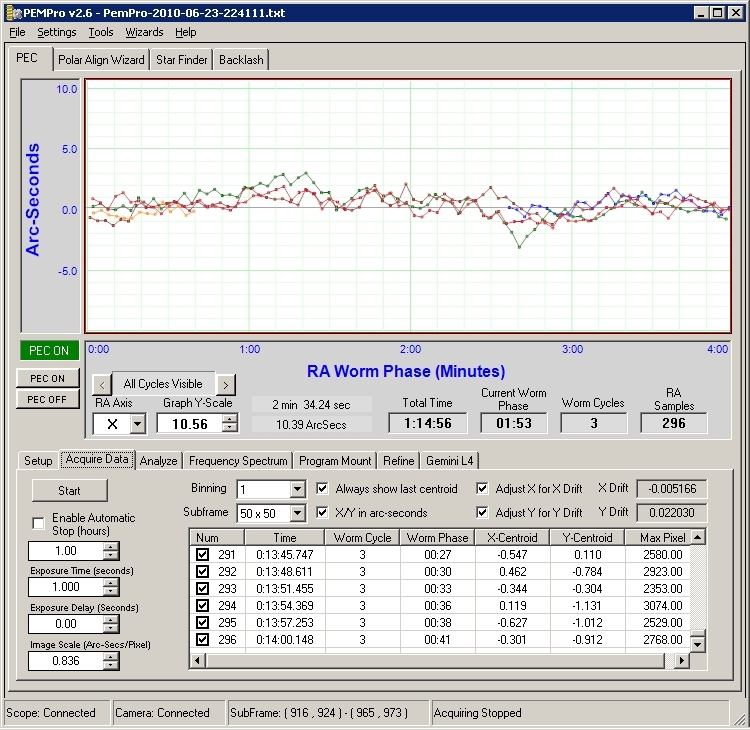

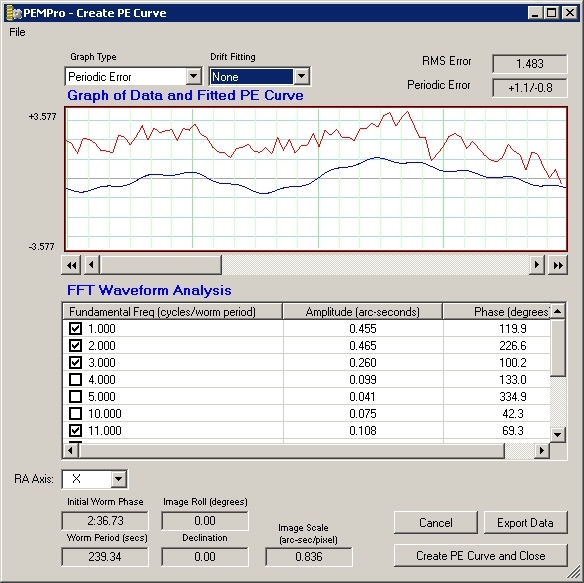

(Clicking on the PemPro images will open a larger version to better see the details)

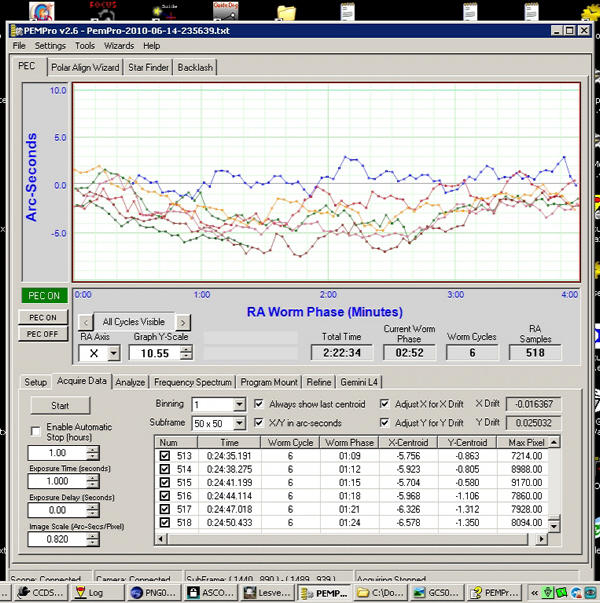

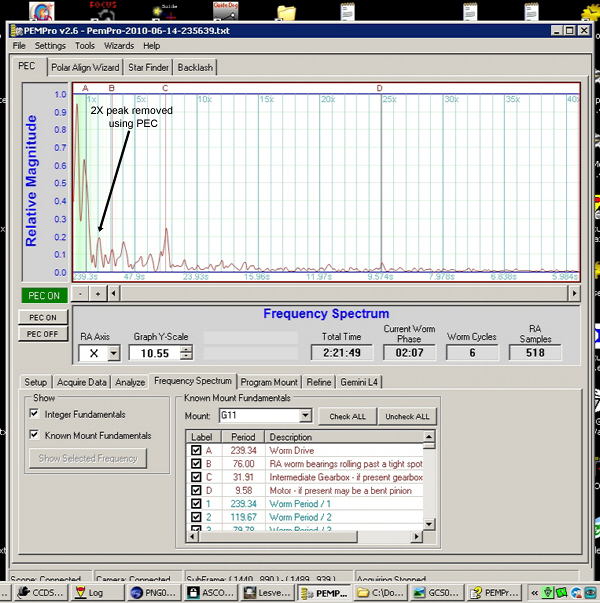

Round 1 - Does this block perform as good as it looks?

Attempting to isolate the cause of the 2X peak growth, the block assembly was taken apart and carefully reassembled. I couldn't find anything that may have cause this increase in the 2X spike.