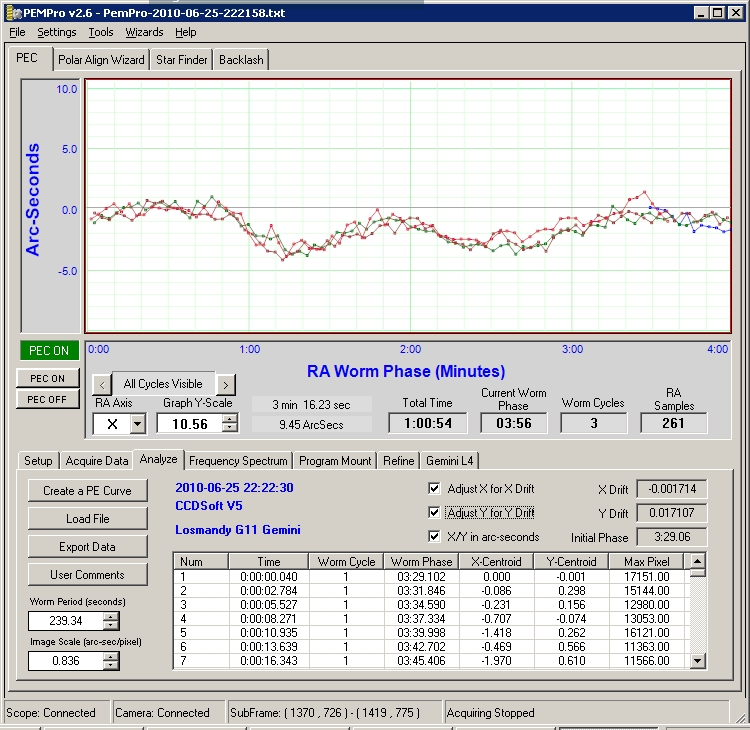

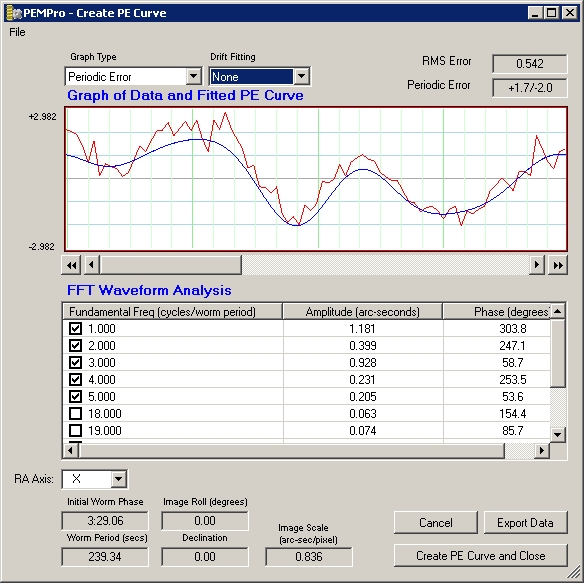

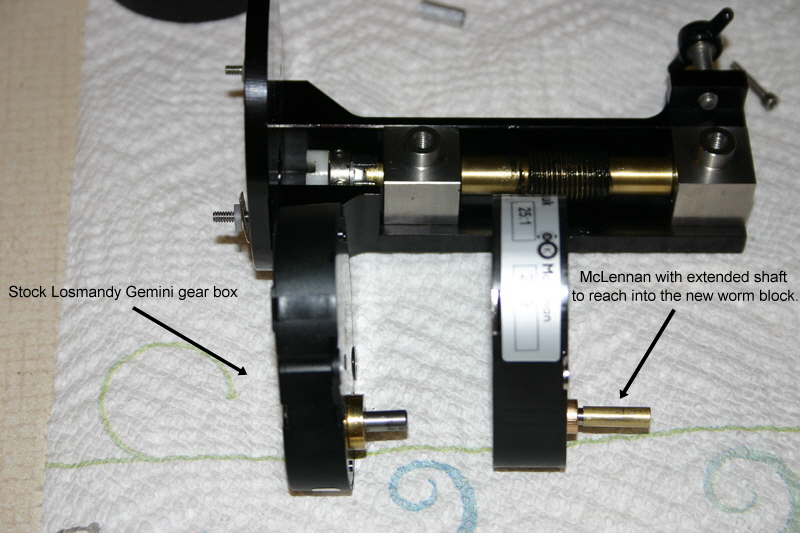

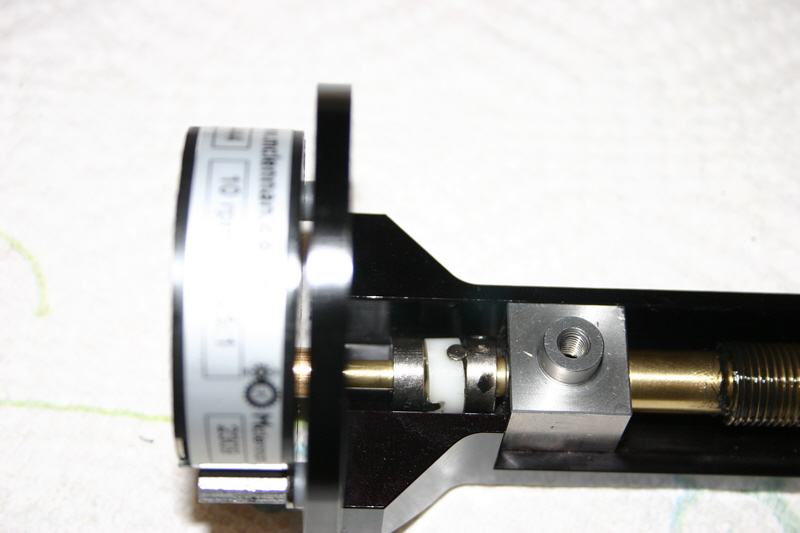

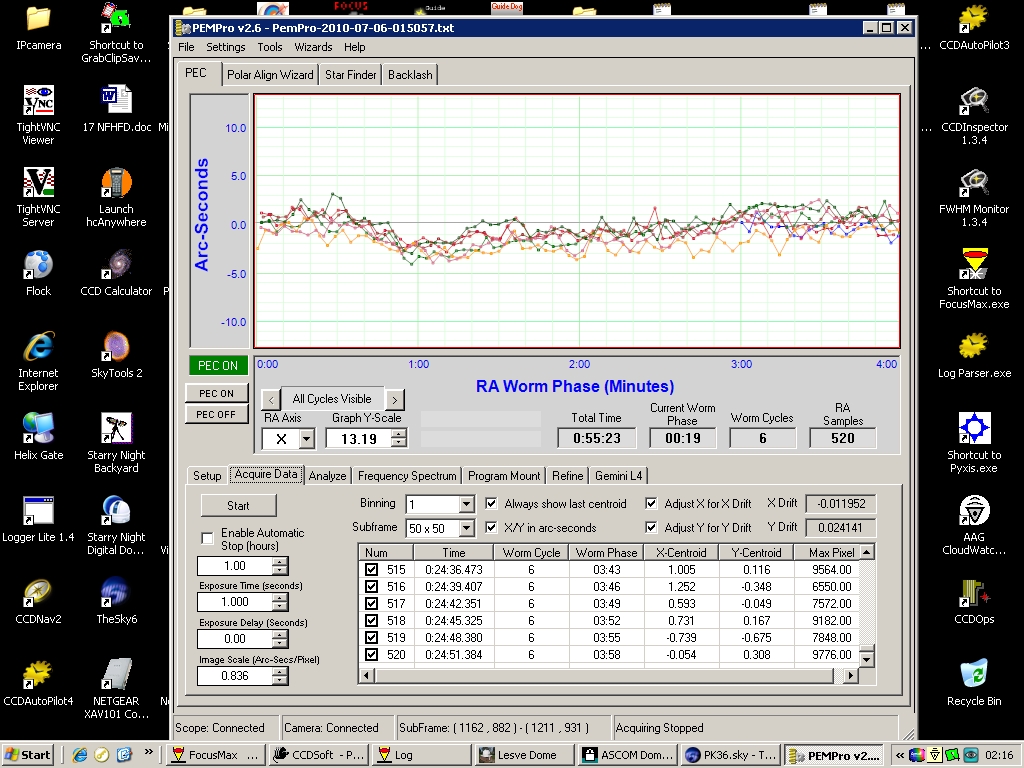

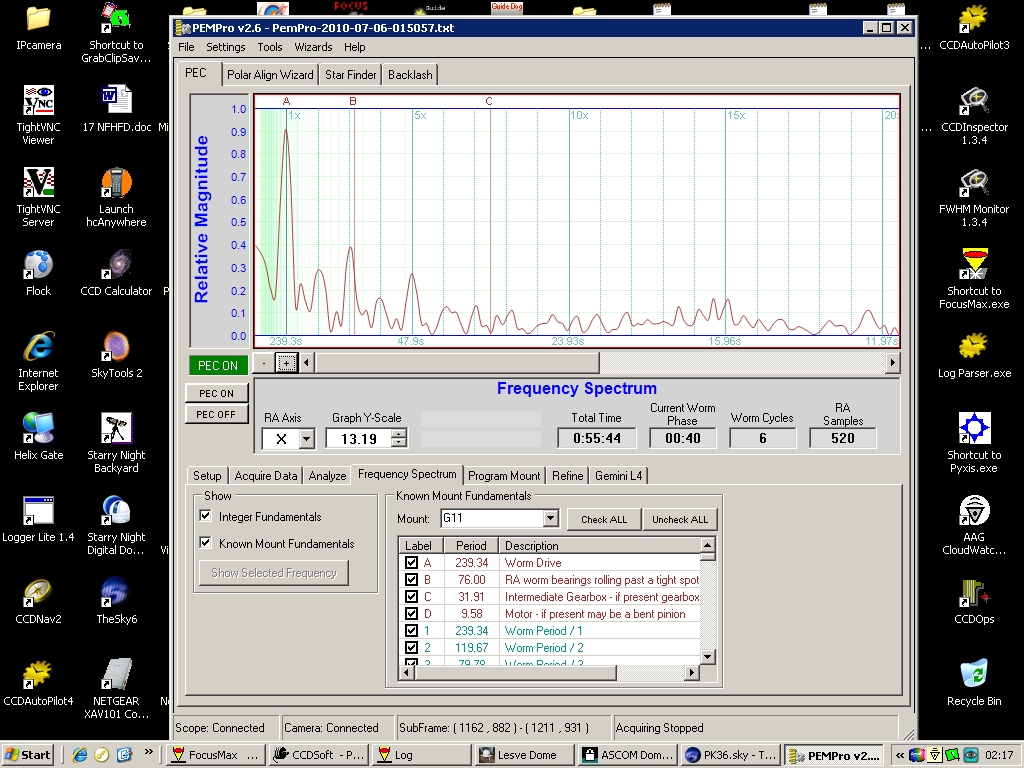

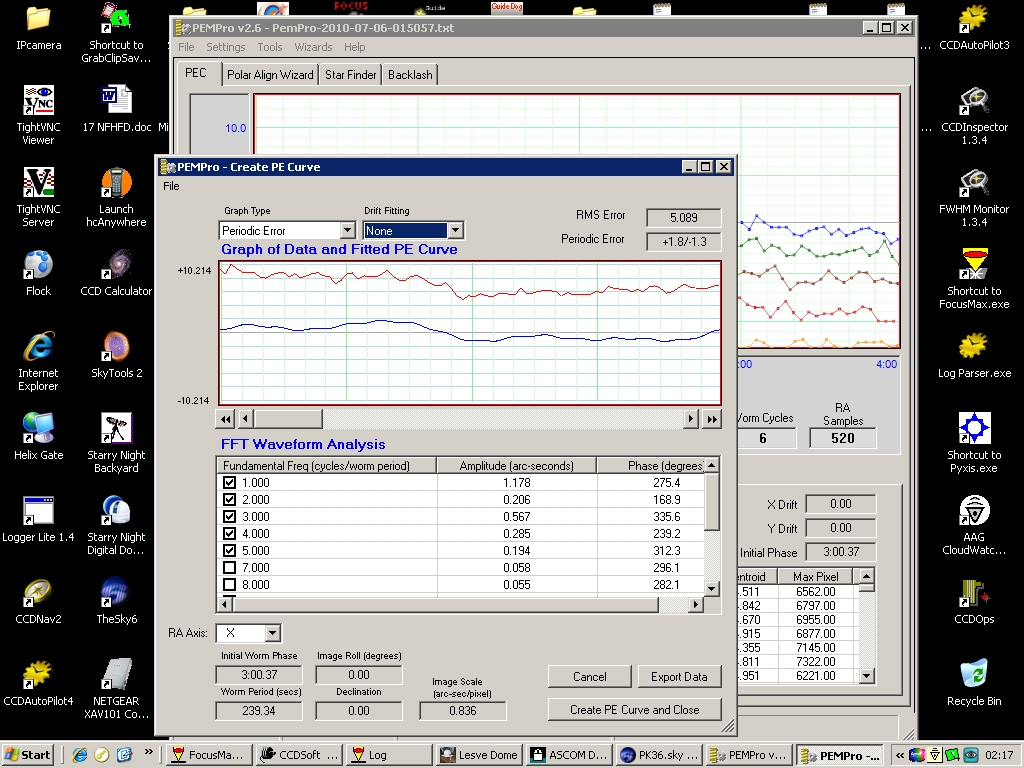

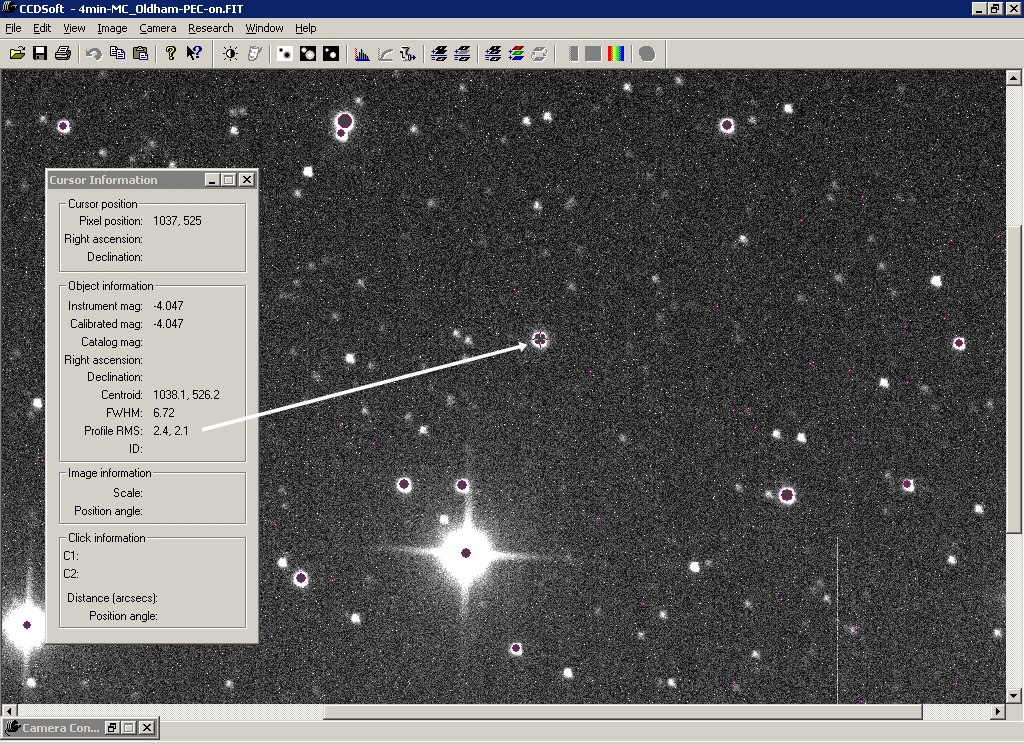

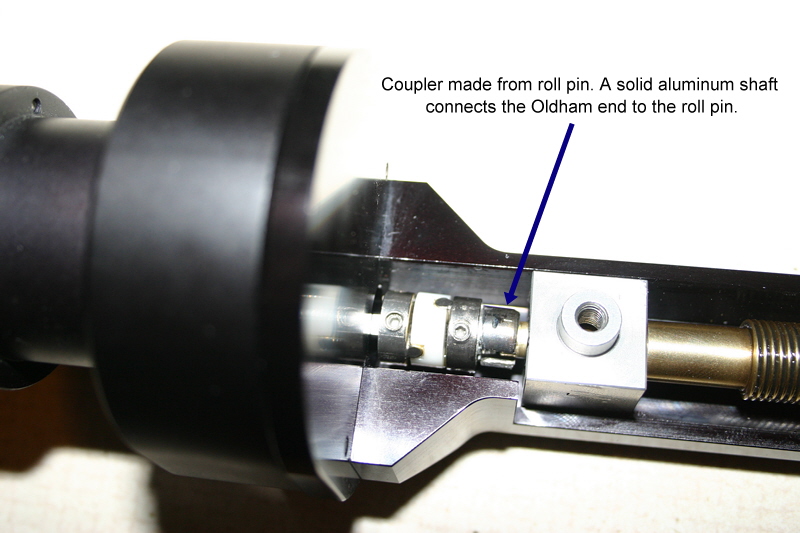

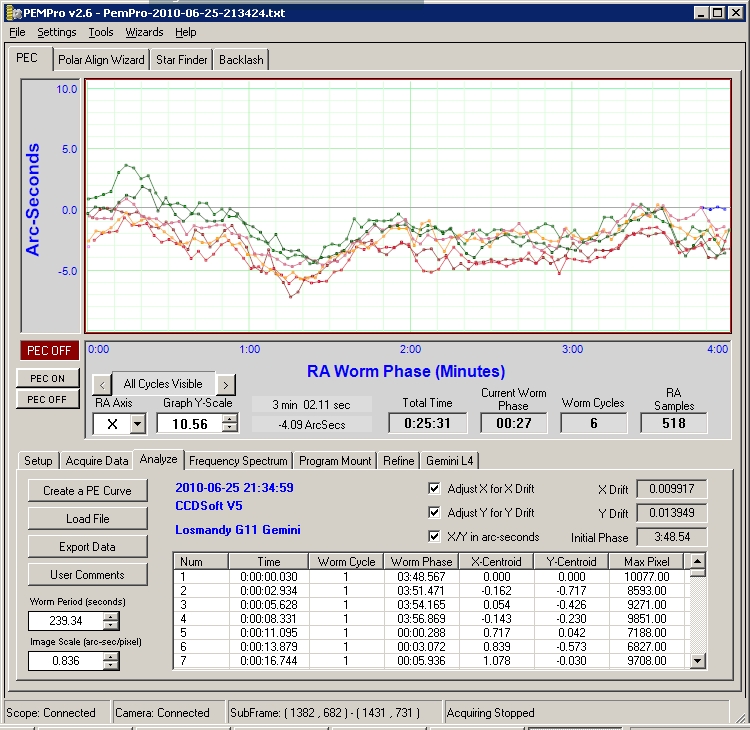

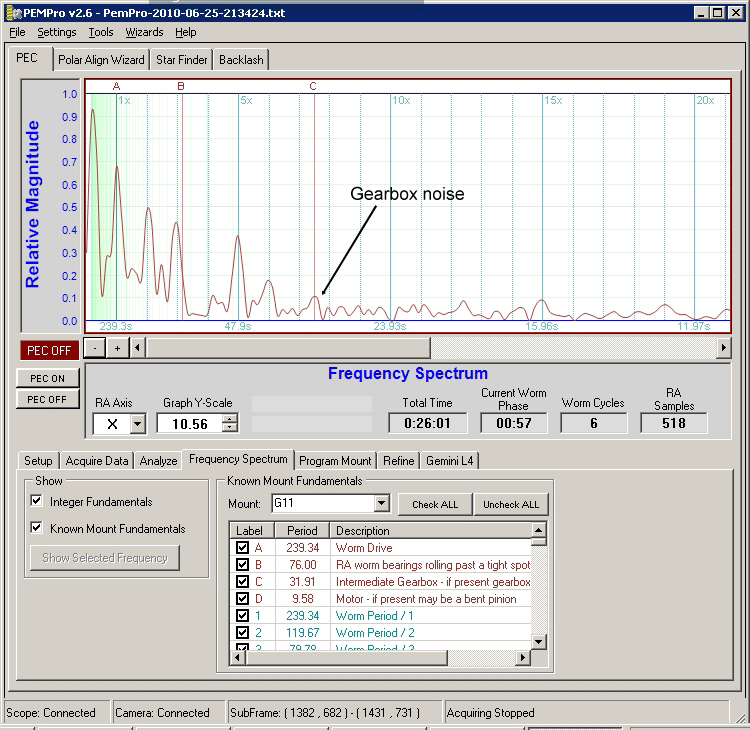

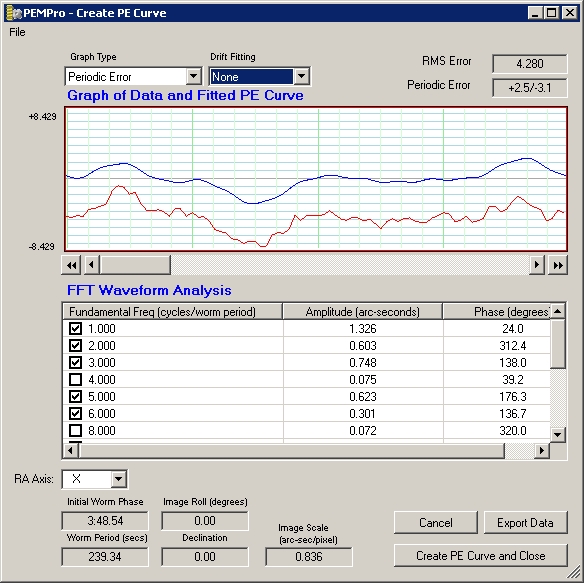

Test series of the original Losmandy Gemini gearbox and the high precision McLennan gearbox using the Oldham coupler. The new block assembly uses a longer Ruland flexible disc coupler and due to a thicker mounting plate it's not possible to use the original Oldham coupler. I made a temporary coupler to use the Oldham with the stock gearbox for this test. PemPro V2 was used to measure PE, generate PEC and plot the performance results.

This series of tests include:

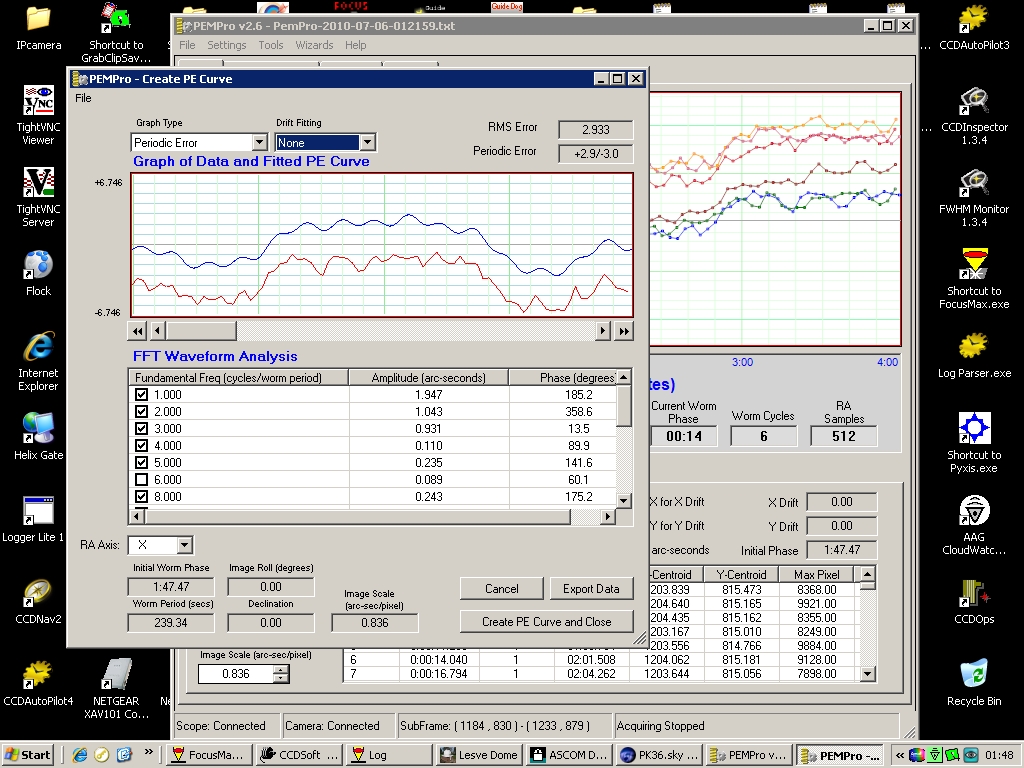

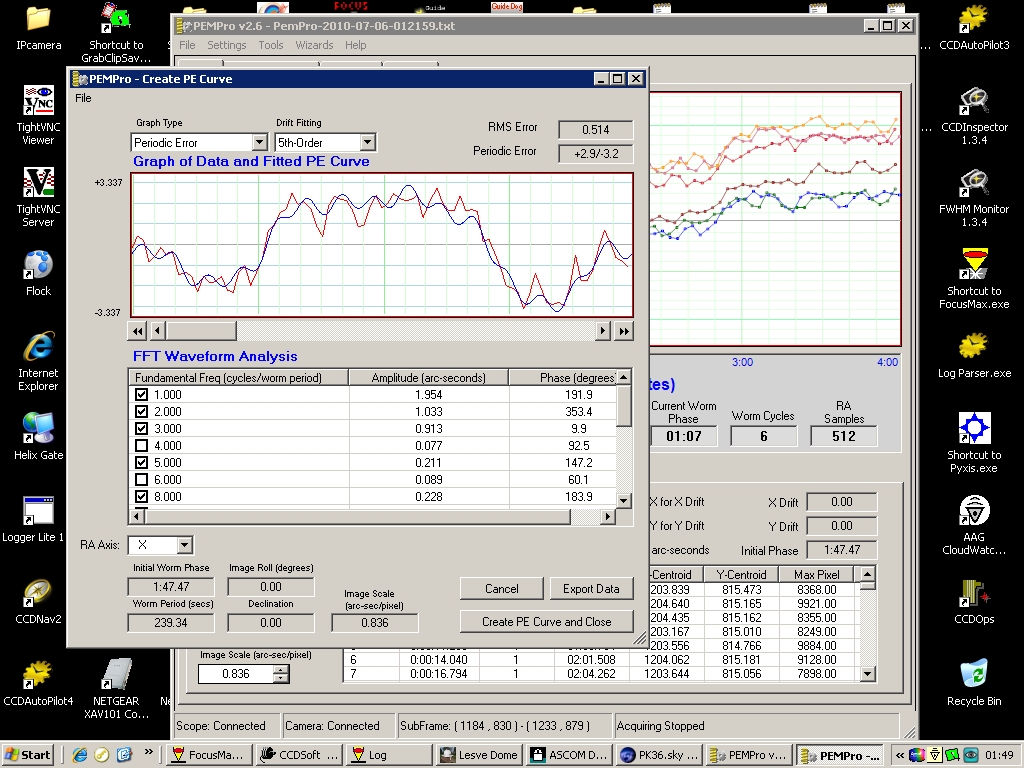

Note: PemPro does allows you to fine tune the PEC profile by adjusting drift and delays. I've included drift fitting screen shots to show 'none' and the best fit for comparisons.

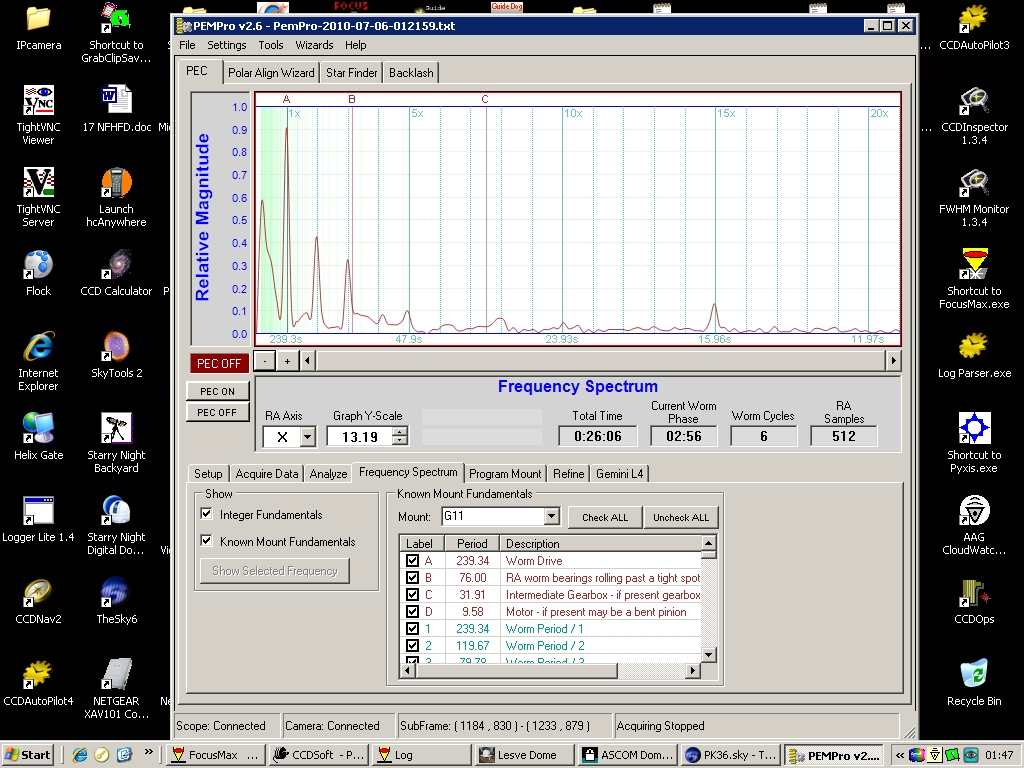

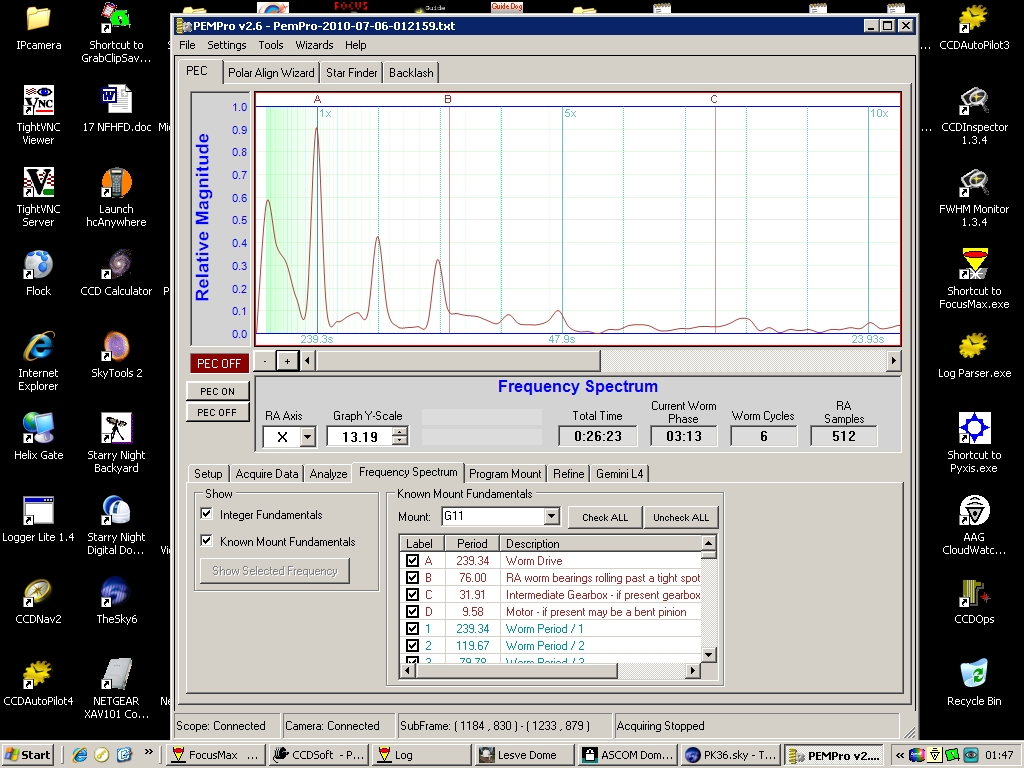

Oldham coupler with Losmandy Gemini stock gear box tests

(Clicking on the images will open a larger version to better see the details)

Note the .11 arc second peak gearbox noise at fundamental C which is the focal point of this test. Because it doesn't fall on a fundamental frequency this peak can not be successfully removed with PEC.