Based on others experience having reported good results with ceramic bearings reducing the '76 sec' error I decided to give it a try and ordered Kit 8421 from VXB. At $39 each and using 3 bearings, it was a $120 experiment. I expected good results after reading some of the details on how these are made and their low rolling friction characteristics but was surprised how bad they performed. Below is only a small sample of the several tests conducted over a few nights to try to make these expensive bearings perform at least as well as their steel counterparts.

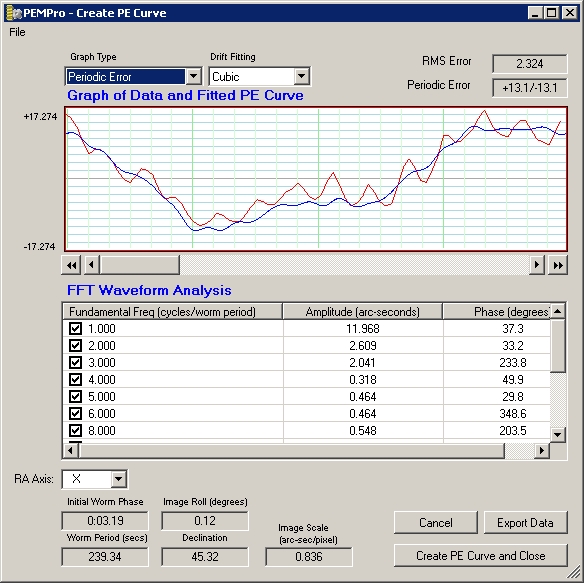

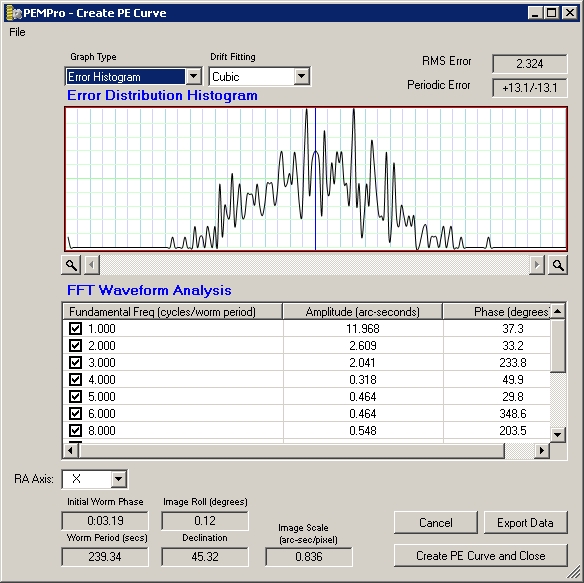

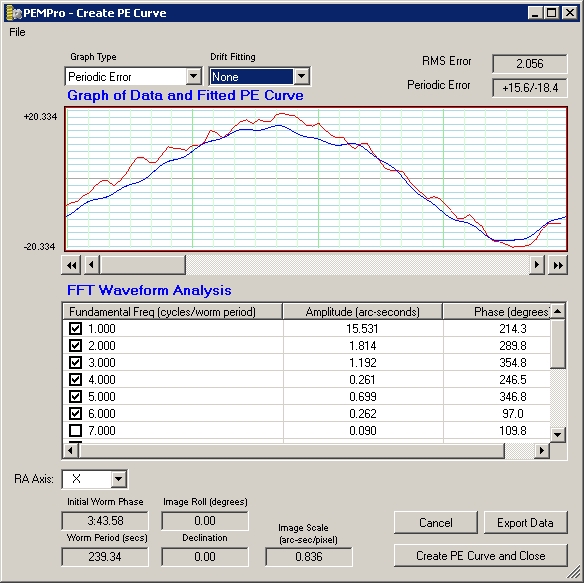

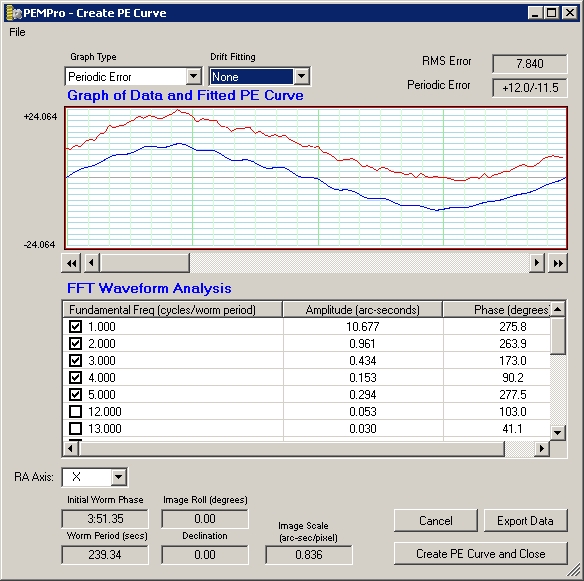

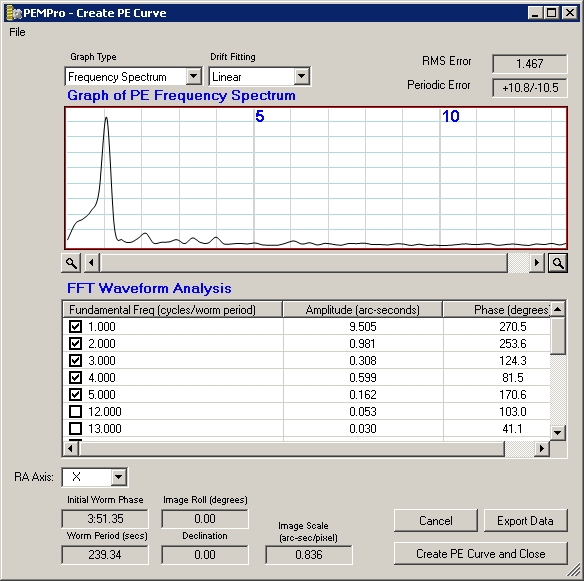

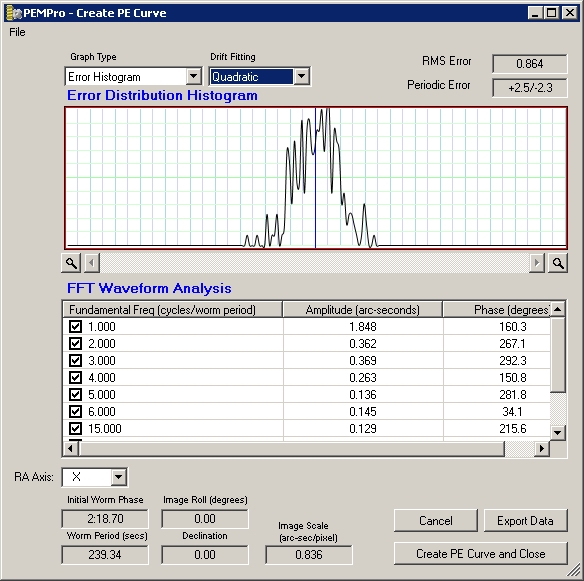

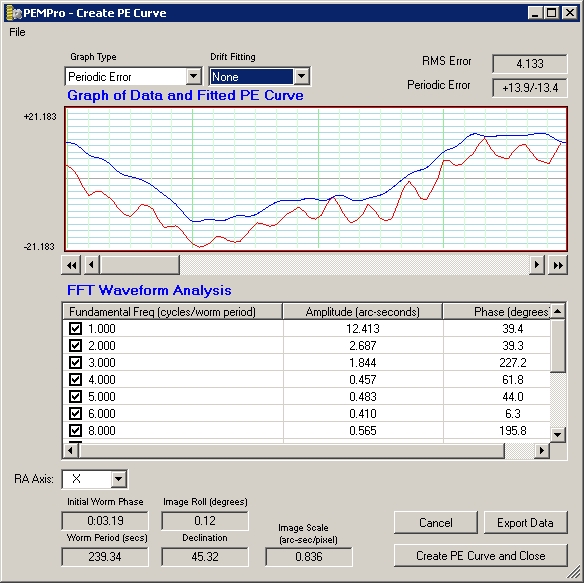

Note: PemPro does allows you to fine tune the PEC profile by adjusting drift and delays. I've included drift fitting screen shots to show 'none' and the best fit for comparisons.

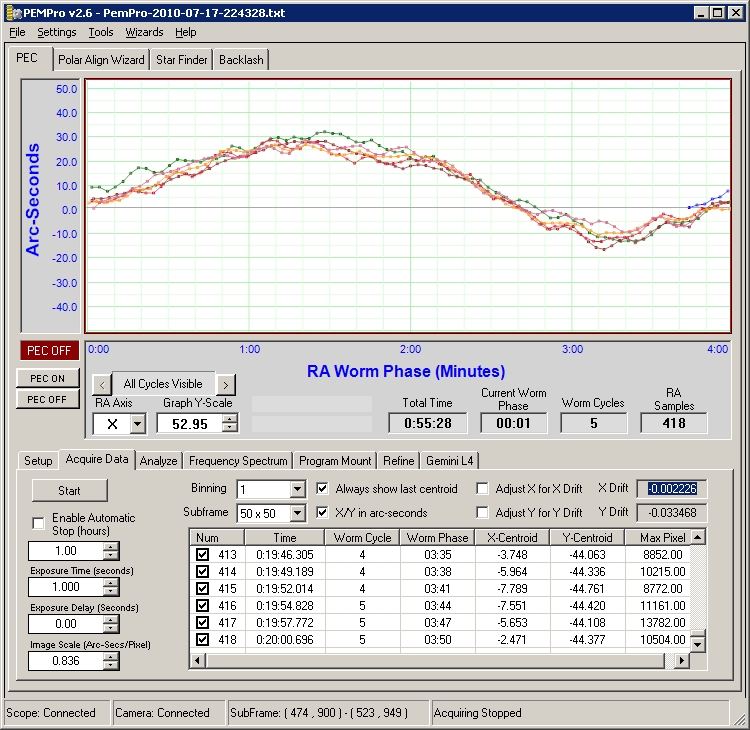

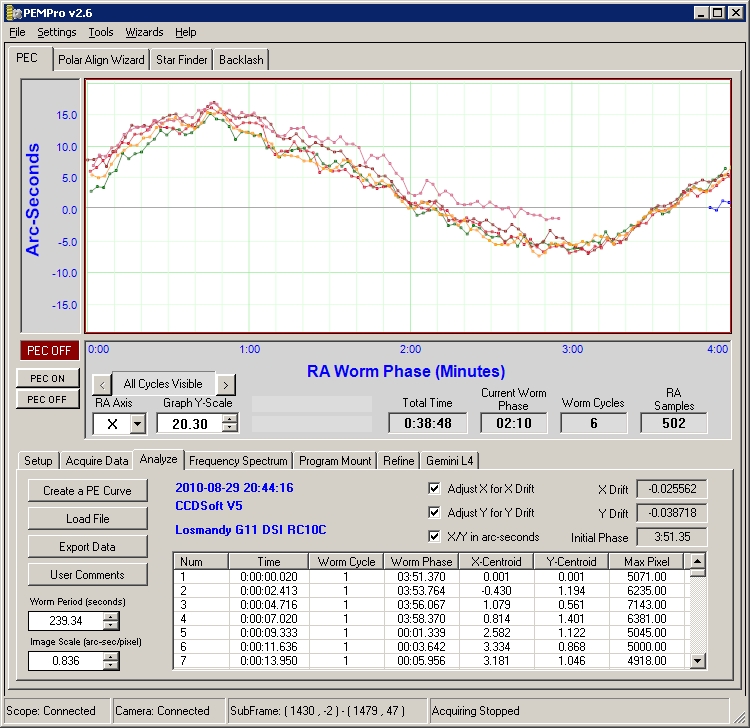

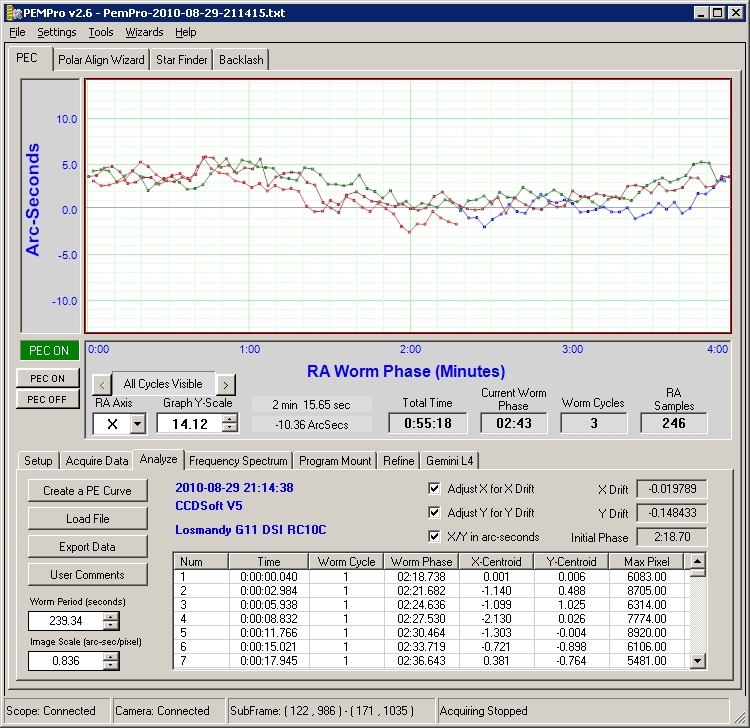

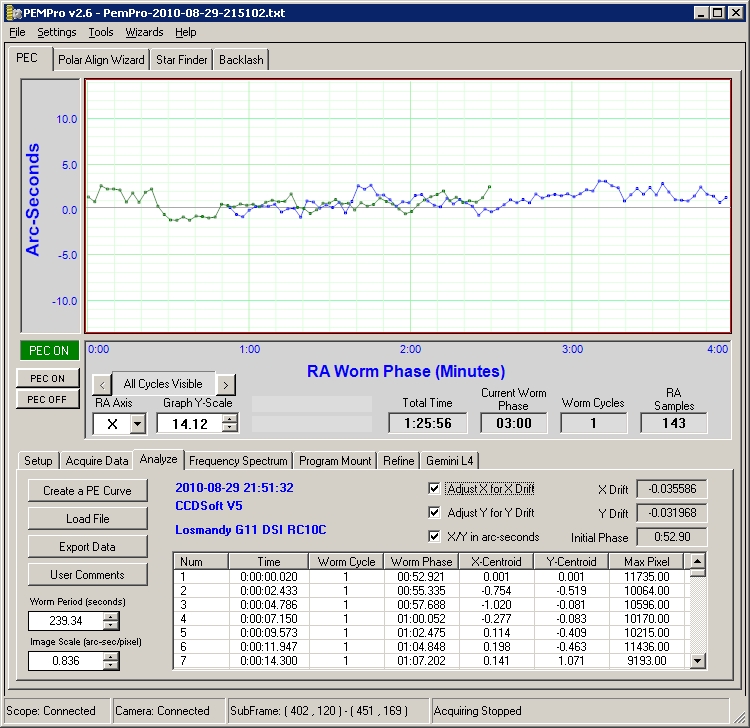

Ceramic bearings tested with McLennan gearbox and Ruland coupler.

(Clicking on the images will open a larger version to better see the details)

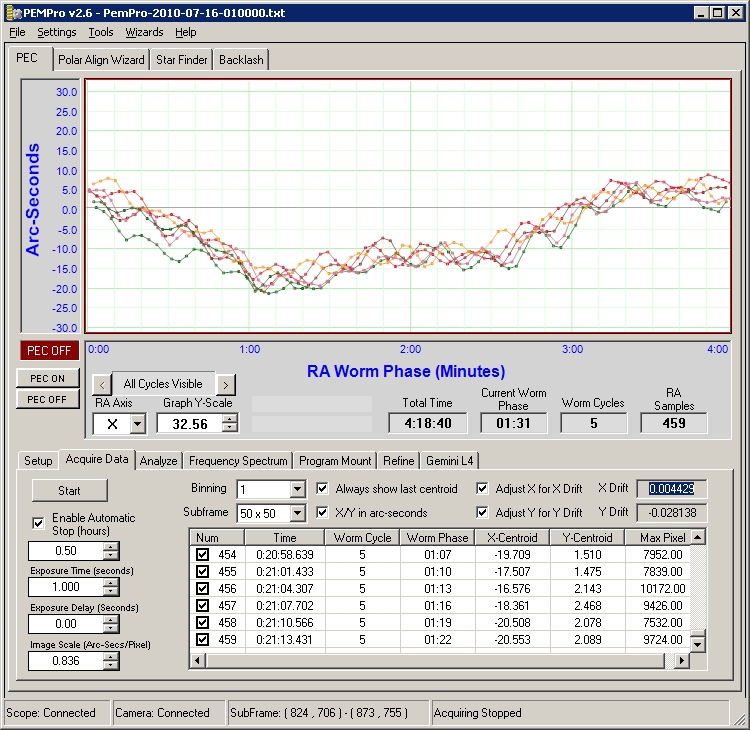

The plot pattern also takes on a sinusoidal shape.

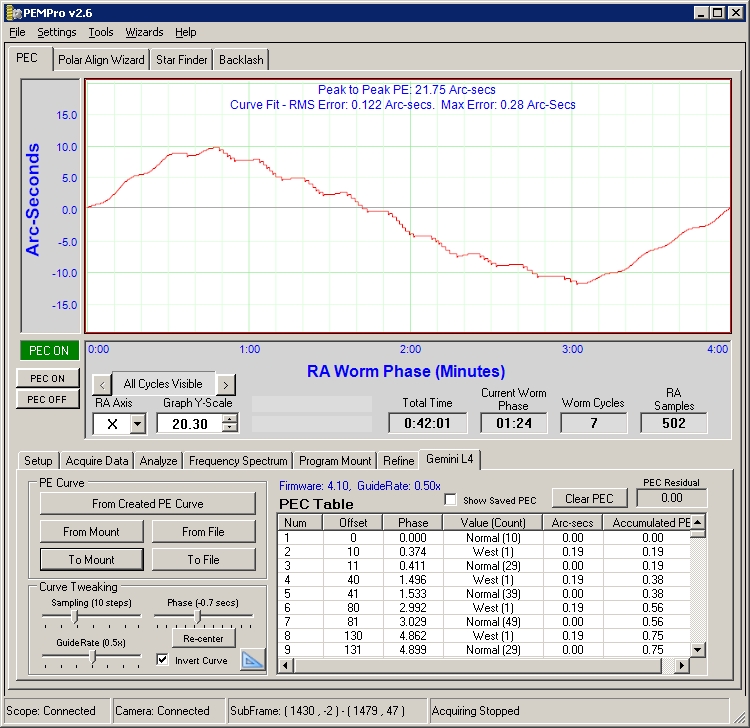

Also high is the PE coming in at a whopping +13 -13 arc seconds peak-peak.

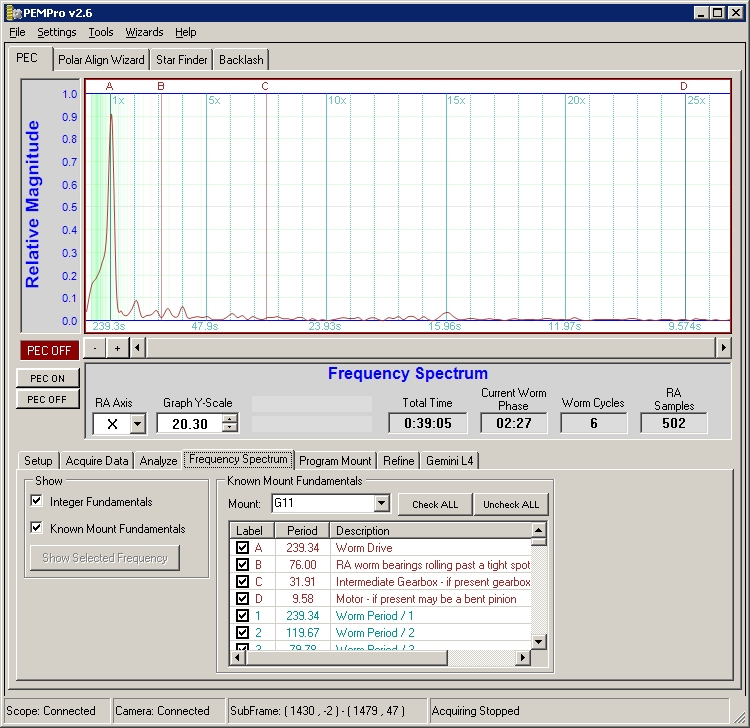

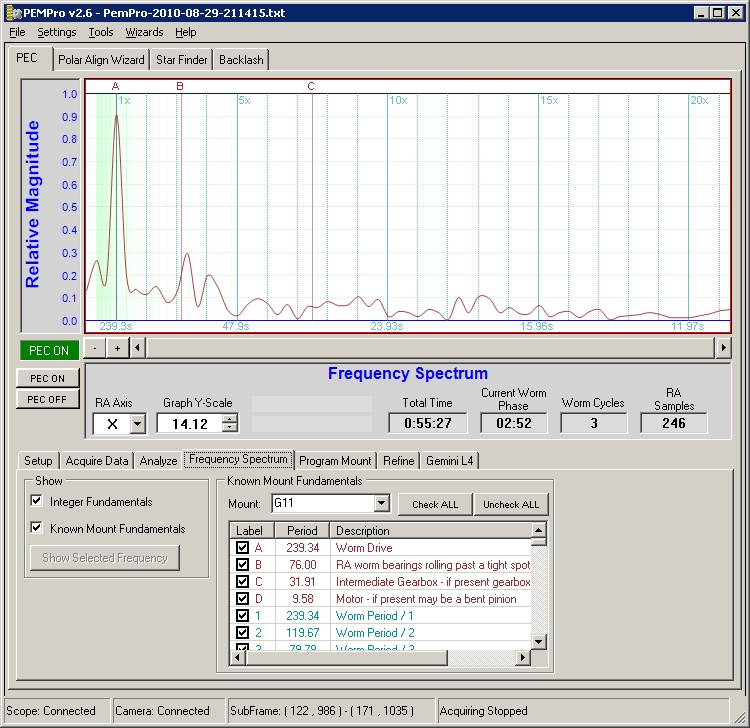

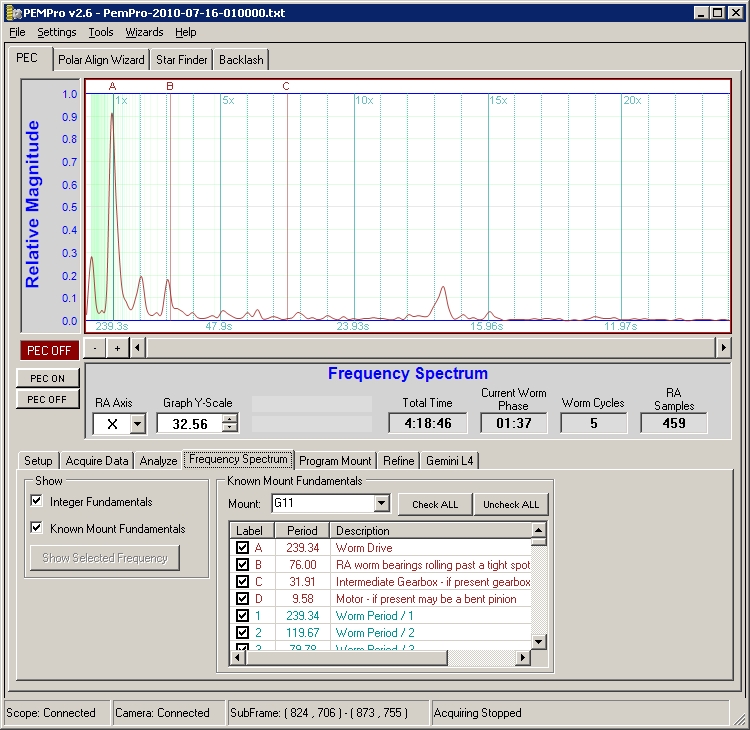

Note: The fundamental at 'C' has been eliminated with the McLennan gearbox that was used for this test.

The 3rd fundamental value in the FFT Waveform Analysis section shows a value higher than the steel bearings.

This shows the 3 ceramic bearing did nothing to reduce this error but caused a big increase in PE.